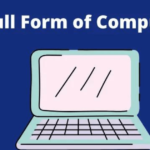

Friends, Microsoft has provided us with an endless number of features, one of them is Microsoft Word, which allows us to quickly type and generate a basic document. So in this article we will know that What Is MS Word? Top Features Of MS Word.

This post will teach us the basics of MS Word, including how to work with it and generate documents.

I will go through the essential features of using a Word document and the basic operations of working with Word in this post. Now let’s open the Word document. Friends, let’s get going.

Table of Contents

What is MS WORD?

Richard Brodie and Charles Simonyi invented Microsoft Word in 1983. Microsoft Word functions similarly to a file that we can store on our computer and save our data in. The system .doc file extension is saved with the file. With Microsoft Word, you can create both simple and complex documents and easily insert images.

To learn about MS PowerPoint Please Visit the Link

Important Features of Microsoft Word

It has some incredible characteristics; let’s examine them now.

File

Initially, as you can see, there are options for saving your file and opening a new document please click on open. To send the file via email, click the share button. Alternatively, you may print it by selecting the print option.

Home

You may adjust the heading, font size, and alignment, find the right words, and replace them by pressing the Home button.

Insert

This keyword offers us a lot of alternatives because it allows us to enter photographs, links, and new tables. Simply click the enter button.

Draw

With a draw, you can draw any pictures.

Design

Page titles can be changed based on design. Additionally, you can use the Design Option to fill in the colors.

Layout

The layout enables you to adjust the page’s margin.

Hence, you can use the techniques I’ve given to modify the formatting of your page.

To learn About MS Excel Please Read the Link

Shortcuts Keys For MS Word

You can work more quickly and effectively using the keyboard shortcuts listed below for Word documents.

| Action | Shortcut |

|---|---|

| Save document | Ctrl + S |

| Copy | Ctrl + C |

| Paste | Ctrl + V |

| Cut | Ctrl + X |

| Undo | Ctrl + Z |

| Redo | Ctrl + Y |

| Select all | Ctrl + A |

| Find | Ctrl + F |

| Replace | Ctrl + H |

| Bold | Ctrl + B |

| Italic | Ctrl + I |

| Underline | Ctrl + U |

| Align left | Ctrl + L |

| Align centre | Ctrl + E |

| Align right | Ctrl + R |

| Justify | Ctrl + J |

| Increase font size | Ctrl + ] |

| Decrease font size | Ctrl + [ |

| Insert hyperlink | Ctrl + K |

| Insert page break | Ctrl + Enter |

| Insert date and time | Alt + Shift + D |

| Open print dialog | Ctrl + P |

| Toggle between open documents | Ctrl + F6 |

| Close current document | Ctrl + W |

| Zoom in | Ctrl + Plus (+) |

| Zoom out | Ctrl + Minus (-) |

| Reset zoom | Ctrl + 0 (zero) |

| Word count | Ctrl + Shift + G |

For better understanding of Web Hosting type please click on Link

portable balancer

Portable Balancer: Balanset-1A for Precision Balancing and Vibration Analysis

The portable balancer known as Balanset-1A is an innovative tool that revolutionizes the process of dynamic balancing and vibration analysis. This dual-channel device is expertly engineered to accommodate a wide variety of rotors, including those found in crushers, fans, mulchers, augers on combines, shafts, centrifuges, and turbines. Its versatility makes it an essential addition to many industrial applications, from manufacturing to maintenance services.

Features of Balanset-1A

At the heart of the Balanset-1A lies a suite of features that enhance its functionality and usability. The device includes two vibration sensors and a laser tachometer, which work collaboratively to deliver high precision results. Whether measuring vibration levels or rotational speeds, the Balanset-1A provides actionable data that allows operators to make informed decisions regarding machine performance and maintenance.

Vibrometer Mode: This mode allows for in-depth analysis of machine vibrations, measuring critical parameters like rotational speed (RPM) and phase angles. The fundamental frequency component and overall vibration levels are monitored, providing insights necessary for effective balancing.

Balancing Modes: Operators can perform single and two-plane balancing, which is crucial for reducing vibrations across various rotor types. The polar graph feature enables users to visualize imbalances and accurately position weights for rectification.

Measurement Logging: The device facilitates comprehensive data storage options, allowing users to save and retrieve past measurement sessions for future reference. This capability is invaluable for ongoing maintenance and analytical studies.

Tolerance Calculator: The Balanset-1A features a built-in calculator that determines acceptable balancing tolerances according to international standards (ISO 1940), ensuring compliance and operational efficiency.

Chart Representation: Users can access various chart formats that visually represent vibration data, enabling quick interpretation of machine conditions and vibration trends.

Technical Specifications

The technical prowess of the Balanset-1A is underscored by its robust specifications. The device features two vibration sensors (with optional extension cables), an optical sensor for precise RPM measurements, and a user-friendly USB interface for easy connection to PCs. Its capabilities are further expanded with software designed specifically for in-depth analysis.

Measurement Channels: 2 for vibration and 1 for rotational speed

Vibration Velocity Measurement Range: 0 to 80 mm/s with a frequency range from 5 to 550 Hz

Measurement Accuracy: Limits of permissible absolute measurement error at В±(0.1 + 0.1*Vi)

Power Requirements: Operates on 140-220VAC power

Weight: Approximately 4 KG, making it truly portable

Applications in Various Industries

The adaptability of the Balanset-1A makes it suitable for a multitude of industrial sectors. In manufacturing facilities, for instance, an efficient portable balancer enhances equipment reliability, minimizes downtime, and maximizes productivity by ensuring that machinery operates at optimal balance. This not only extends the lifespan of equipment but also leads to significant reductions in energy consumption and maintenance costs.

User Experience and Setup

Setting up the Balanset-1A is straightforward and user-friendly, catering to both seasoned professionals and newcomers to balancing technology. The device comes with comprehensive manuals and documentation that guide users through initial setup, operational procedures, and troubleshooting. Additionally, the Balanset-1A supports multiple languages, making it accessible to a diverse range of users in various locations around the globe.

Cost and Availability

The Balanset-1A is competitively priced at €1,751, reflecting its advanced capabilities and robust design. Customers can purchase the device directly from various online platforms, including eBay and Amazon, ensuring ease of access for those seeking to invest in a reliable portable balancer. The option to become a member for discounts also appeals to frequent buyers, further incentivizing the purchase of this essential tool.

Conclusion: A Must-Have Tool for Professionals

In conclusion, the Balanset-1A stands out as a remarkable portable balancer that combines cutting-edge technology with user-centric features. Its extensive range of applications, flexibility in handling different rotor types, and precise measurement capabilities establish it as a vital instrument for professionals across a variety of industries. Investing in the Balanset-1A ensures that operators have the necessary tools to maintain equipment performance, enhance productivity, and promote efficient operations. Experience the benefits of dynamic balancing with Balanset-1A—where precision meets portability.

Watch YouTube Short

Balanset-1A: A Revolutionary Tool for Rotor Balancing

In the world of industrial maintenance and repair, rotor balancing plays a crucial role in ensuring the efficient operation of machinery. The Balanset-1A is a state-of-the-art tool designed specifically for this purpose, offering a versatile solution for both single-plane and dual-plane balancing tasks.

Understanding Rotor Balancing

Rotor balancing is essential for reducing vibration and extending the lifespan of machinery. The procedure can be classified into two main types: single-plane (static) balancing and dual-plane (dynamic) balancing.

Single-Plane Balancing

Single-plane balancing is typically performed on narrow, disc-shaped rotors that do not exhibit significant axial runout. Examples of such rotors include:

Narrow grinding wheels

Pulleys for belt drives

Disc flywheels

Gears

Couplings

Lathe chucks

Narrow fans

These components are generally balanced in one plane because their mass distribution allows for effective correction without the need for additional planes.

Dual-Plane Balancing

Dual-plane balancing, on the other hand, is necessary for longer, shaft-like rotors that are supported at two points. These rotors require correction in two planes to account for their increased complexity and potential for uneven weight distribution. Typical examples include:

Rotors of electric motors and generators

Rotors of compressors and pumps

Impellers of turbines and fans

Wide grinding wheels

Spindles

Shafts of milling machines with beaters

The choice between single-plane and dual-plane balancing is determined by the rotor’s structural characteristics, ensuring precise and efficient correction of imbalances.

Why Choose Balanset-1A?

The Balanset-1A stands out as a premier choice for rotor balancing due to its precision, versatility, and ease of use. Here are some reasons why it is a preferred tool:

Precision: The Balanset-1A provides accurate measurements and adjustments, crucial for achieving optimal rotor performance.

Versatility: Suitable for both single-plane and dual-plane balancing, it adapts to various rotor types and sizes.

User-Friendly: Designed with the user in mind, the Balanset-1A is easy to operate, reducing the learning curve for technicians.

Durability: Built to withstand the rigors of industrial environments, ensuring long-term reliability and performance.

Implementing Balanset-1A in Maintenance and Repair

Incorporating the Balanset-1A into maintenance and repair procedures can significantly enhance the efficiency and longevity of machinery. By ensuring precise rotor balancing, this tool helps prevent excessive vibration, reduce wear and tear, and ultimately save on costly repairs and downtime.

For industries reliant on high-performance machinery, the Balanset-1A offers a strategic advantage, ensuring that operations run smoothly and efficiently.

Conclusion

The Balanset-1A is an invaluable asset for any maintenance team, providing the precision and versatility needed to tackle both static and dynamic rotor balancing challenges. By investing in advanced tools like the Balanset-1A, businesses can optimize their maintenance processes, improve machinery reliability, and achieve significant cost savings in the long run.

Contact Information:

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on Facebook Marketplace

Balanset-1A OEM on Machinio